Essential Guide to 55-Gallon and Industrial Drum Solutions

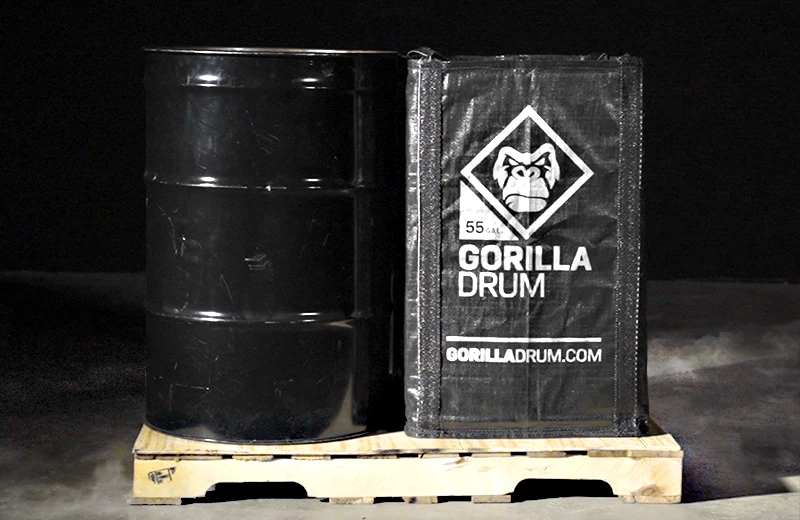

For decades, the 55 gallon drum has been the default solution for industrial storage and shipping. From chemical processing and manufacturing to agriculture and environmental services, businesses across industries rely on storage drums and shipping drums to move and contain critical materials safely.

However, as operational demands evolve, traditional drum solutions are increasingly revealing their limitations. Weight, durability concerns, inefficiencies in transport, and long-term costs have led many organizations to seek modern alternatives that outperform the standard steel drum or plastic barrel.

This is where GORILLA DRUM™ – The Original Steel Drum Alternative redefines what industrial drums can and should be.

This essential guide explores the role of traditional 55 gallon drums, compares them to modern alternatives, examines material differences across drum types, and helps decision-makers choose the best drum solution for storage and shipping needs—all while demonstrating why Gorilla Drum™ represents the next generation of industrial drum technology.

Understanding the Role of the 55-Gallon Drum in Industrial Applications

The 55 gallon drum container has long been regarded as the industry standard for bulk material handling across a wide range of sectors. Its standardized dimensions make it universally compatible with pallet systems, forklifts, drum dollies, pumps, and other material-handling equipment used in warehouses, manufacturing facilities, and transportation networks around the world. This consistency has allowed businesses to streamline logistics and build processes around a single, reliable container size.

As storage drums, 55 gallon drums are used to safely hold liquids, solids, and semi-solids for both short-term and long-term storage. As shipping drums, they are relied upon to transport regulated and non-regulated materials efficiently through complex supply chains. Their versatility has made them a foundational component in industrial operations where containment, mobility, and efficiency are essential.

Traditional 55 gallon drums are commonly used for a wide range of materials, including:

- Chemicals and solvents used in manufacturing and processing

- Oils, lubricants, and fuels that require secure containment

- Food ingredients and additives where cleanliness and compatibility are critical

- Industrial waste and byproducts generated during production

- Agricultural materials such as fertilizers and treatments

- Environmental cleanup operations that demand dependable containment

The familiar 55 gallon blue barrel is most often associated with plastic drum construction, valued for its corrosion resistance and lighter weight. In contrast, steel drums have traditionally dominated more rugged applications that require higher impact resistance and stacking strength. Each option has earned its place based on the demands of specific industries.

However, despite their widespread use, traditional drum designs reveal limitations when evaluated through the lens of modern operational priorities. Steel drums introduce challenges related to weight, handling safety, and corrosion, while plastic drums may struggle with impact resistance and long-term durability. As efficiency, safety, and total cost of ownership become increasingly important, organizations are reexamining the role of the 55 gallon drum and exploring advanced alternatives that deliver greater performance and long-term value.

How Traditional 55-Gallon Drums Compare to Modern Alternatives

The Legacy of Traditional 55-Gallon Drums

The 55 gallon drum has long been a cornerstone of industrial storage and transportation. Its standardized size, compatibility with material-handling equipment, and ability to contain a wide range of products made it a practical solution across manufacturing, chemical processing, agriculture, and logistics. Early drum design focused on one primary objective: durability through mass. Strength was equated with thickness and weight, which led steel drums to become the dominant choice for industrial applications.

Steel drums earned their reputation by withstanding rough handling, heavy stacking loads, and demanding transport conditions. A 55 gallon steel drum could be dropped, rolled, and stacked with confidence, making it the preferred option for hazardous materials and high-value products. As industries expanded and diversified, plastic drums were introduced to address specific limitations of steel. Industrial plastic drums offered corrosion resistance and reduced weight, making them attractive for certain chemicals and applications where rust or chemical reactions were a concern.

Despite their widespread adoption, both steel and plastic drums reflect design priorities of an earlier industrial era. Over time, their limitations have become increasingly apparent. Steel drums, while strong, are extremely heavy. That weight increases shipping costs, raises the risk of worker injury during handling, and adds strain to material-handling equipment. Plastic drums, although lighter, can crack, warp, or fail when exposed to repeated impacts, extreme temperatures, or long-term outdoor storage.

Both traditional options often require frequent replacement or reconditioning to remain in service. In addition, empty drum returns present a persistent challenge. Standard drums occupy the same amount of space whether full or empty, consuming valuable transportation capacity and warehouse space. As operations scale and profit margins tighten, these inefficiencies compound, driving up total cost of ownership.

The Shift Toward Advanced Drum Alternatives

Modern industrial operations demand more from their storage drums and shipping drums than ever before. Today’s drum solutions must support efficiency, safety, and sustainability while maintaining consistent performance across diverse environments. Simply holding material is no longer enough.

Organizations now look for drum systems that can reduce transportation and handling costs by minimizing weight and damage-related losses. Worker safety has become a top priority, requiring containers that are easier to handle without sacrificing durability. Consistent performance in harsh environments—whether extreme temperatures, repeated impacts, or frequent reuse—is essential. At the same time, sustainability initiatives push companies to adopt solutions that support reuse, reduce waste, and improve overall logistics efficiency.

GORILLA DRUM™ was engineered specifically to meet these evolving demands. As the original steel drum alternative, it was designed from the ground up to address the shortcomings of traditional drum designs. Rather than relying on outdated assumptions about weight and strength, Gorilla Drum™ leverages advanced engineering to deliver durability, efficiency, and long-term value in a single solution.

Performance Comparison: Traditional Drums vs. GORILLA DRUM™

Traditional steel and plastic drums are built on decades-old design principles that prioritize either strength or weight, often forcing users to compromise. Gorilla Drum™ represents a purpose-built evolution, engineered for real-world industrial use where performance, efficiency, and reliability must coexist.

Compared to steel drums, Gorilla Drum™ offers significantly reduced weight, which lowers freight costs and minimizes handling risks. This lighter profile improves worker safety while maintaining the strength required for demanding industrial environments. When compared to typical plastic drums, Gorilla Drum™ delivers exceptional impact resistance, reducing the likelihood of cracking or failure during transport and handling.

Structural integrity is another key differentiator. Gorilla Drum™ is designed for repeated use, maintaining its shape and performance across multiple cycles without the need for constant replacement or reconditioning. Its optimized shape and construction also improve stacking stability and transport efficiency, allowing organizations to maximize space utilization and streamline logistics.

Rather than forcing a choice between the rugged strength of a steel drum and the convenience of a plastic container, GORILLA DRUM™ provides a balanced, modern solution. It combines durability, efficiency, and reliability into a single drum system designed for today’s industrial realities—and tomorrow’s operational challenges.

Steel, Plastic, and Collapsible Drums: Key Differences

Understanding the differences between drum materials is essential when selecting storage drums or shipping drums. Each category offers unique characteristics, yet not all are equally suited for modern industrial requirements.

Steel Drums

The steel drum has long been associated with strength and security. A 55 gallon steel drum is often used for hazardous materials, petroleum products, and heavy industrial contents.

Advantages of steel drums:

- High puncture and impact resistance

- Suitable for high-temperature applications

- Widely accepted for regulated shipping

Limitations of steel drums:

- Extremely heavy, increasing transportation costs

- Susceptible to corrosion without internal linings

- Higher risk of injury during handling

- Costly to replace or recondition over time

Steel drums remain common, but their drawbacks have become increasingly apparent in high-volume or repetitive operations.

Industrial Plastic Drums

Industrial plastic drums, including the familiar 55 gallon blue barrel, are widely used for their corrosion resistance and lighter weight.

Advantages of industrial plastic drums:

- Resistant to many corrosive materials

- Lower upfront cost compared to steel

- Easier manual handling

Limitations of plastic drums:

- Vulnerable to cracking under impact

- Performance can degrade in extreme temperatures

- Shorter service life in demanding environments

Plastic drums often trade durability for convenience, which can result in higher long-term replacement costs.

Collapsible Drums

Collapsible drums were introduced to address storage and return-logistics challenges. They reduce empty shipping volume but are often limited in durability and load capacity.

Advantages:

- Reduced empty return space

- Lower storage footprint

Limitations:

- Less rigid structure

- Not ideal for rugged industrial environments

- Often unsuitable for hazardous materials

Why GORILLA DRUM™ Stands Apart

GORILLA DRUM™ was engineered with a clear purpose: to move beyond the limitations of traditional steel drums, industrial plastic drums, and collapsible containers. Rather than adapting an existing design, it was developed as a true high-performance industrial drum alternative—one that aligns with the realities of modern operations where efficiency, safety, and durability must work together.

Traditional drum categories each offer strengths, but they also force compromises. Steel drums deliver strength but add significant weight and cost. Plastic drums reduce weight but often sacrifice impact resistance and longevity. Collapsible drums improve return logistics but may lack the durability required for demanding industrial environments. GORILLA DRUM™ eliminates these tradeoffs by combining the most critical performance attributes into a single, purpose-built solution.

One of the most defining advantages of GORILLA DRUM™ is its strength-to-weight balance. It delivers structural strength comparable to a steel drum while avoiding the excessive weight that drives up freight costs and increases handling risk. This balance allows organizations to maintain confidence in containment and protection without absorbing the operational penalties associated with heavy steel containers.

Impact resistance is another area where GORILLA DRUM™ clearly stands apart. Unlike many industrial plastic drums that can crack or fail under repeated impacts, Gorilla Drum™ is designed to withstand the rigors of real-world handling. Drops, bumps, and transport vibration are inevitable in industrial environments, and this drum is built to perform reliably through them.

Longevity plays a critical role in total cost of ownership. GORILLA DRUM™ offers a long service life that significantly reduces replacement frequency compared to traditional drums. Fewer failures, fewer replacements, and fewer interruptions translate directly into cost savings and operational continuity. Over time, this durability supports both financial efficiency and sustainability goals.

Finally, GORILLA DRUM™ is optimized for shipping, handling, and reuse. Its design supports stable stacking, efficient transport, and compatibility with standard handling equipment. This makes it an ideal solution for storage drums and shipping drums used in high-volume, repeat-use environments.

For organizations that rely on industrial drums to support daily operations, consistency matters. GORILLA DRUM™ delivers reliable performance without compromise, providing a modern alternative that meets today’s demands while preparing businesses for the challenges ahead.

Choosing the Best Drum Solution for Storage and Shipping Needs

Selecting the right 55 gallon drum solution requires more than choosing a material. It involves evaluating how the drum will perform throughout its entire lifecycle—from filling and handling to shipping, storage, and reuse.

Evaluating Storage Requirements

When selecting storage drums, consider:

- Chemical compatibility with stored materials

- Exposure to temperature fluctuations

- Duration of storage

- Stacking and space constraints

Traditional drums may meet basic needs, but Gorilla Drum™ is designed to excel under a wide range of storage conditions while maintaining structural integrity over repeated use.

Optimizing Shipping Efficiency

Shipping drums represent a significant portion of logistics costs. Drum weight, durability, and stackability all affect transportation efficiency.

GORILLA DRUM™ helps reduce shipping costs by:

- Lowering overall shipment weight compared to steel drums

- Reducing damage-related losses during transit

- Improving load stability through consistent drum design

For operations shipping large volumes of 55 gallon drum containers, these efficiencies quickly translate into measurable cost savings.

Enhancing Worker Safety

Handling traditional steel drums presents ergonomic risks due to their weight. Plastic drums may reduce weight but introduce risks related to cracking or failure.

GORILLA DRUM™ improves workplace safety by:

- Reducing handling strain

- Maintaining structural integrity during movement

- Minimizing leaks and failures

Safer drums protect both employees and the materials they manage.

Long-Term Cost Considerations

While initial purchase price is important, total cost of ownership is the true measure of value.

GORILLA DRUM™ delivers long-term savings through:

- Extended service life

- Reduced replacement frequency

- Lower transportation and handling costs

- Decreased product loss due to drum failure

When evaluated over time, Gorilla Drum™ consistently outperforms traditional steel drums and plastic alternatives.

Why Gorilla Drum™ Is the Future of Industrial Drum Solutions

Industries that depend on storage drums and shipping drums are operating in an environment of increasing complexity and expectation. Rising transportation costs, stricter safety standards, and growing sustainability initiatives are reshaping how organizations evaluate even the most familiar tools, including the 55 gallon drum. While traditional drum designs have served industry for generations, they were created for a different era—one where efficiency, ergonomics, and long-term environmental impact were not primary considerations.

Legacy steel and plastic drums were designed to solve a single problem: containment. Over time, those solutions became standardized, but the demands placed on them have evolved. Today, drums must support leaner operations, protect workers, reduce waste, and perform consistently across increasingly global supply chains. These expectations expose the limitations of older designs that rely on excess weight, rigid materials, or short service lifespans.

GORILLA DRUM™ represents a purposeful evolution in industrial drum technology. Designed from the ground up as The Original Steel Drum Alternative, it is not a modification of a traditional steel or plastic drum. Instead, it is a modern solution engineered specifically to meet the performance, safety, and efficiency standards required in today’s industrial environments.

One of the most significant ways Gorilla Drum™ defines the future is through its optimized strength. Traditional steel drums achieve durability by adding mass, which increases shipping costs and makes handling more difficult. Gorilla Drum™ delivers strength without unnecessary weight, allowing organizations to maintain confidence in containment while improving logistics efficiency. Reduced weight directly translates to lower freight expenses, easier handling, and less strain on material-handling equipment.

Durability is another defining factor. Steel drums are vulnerable to corrosion over time, especially when exposed to moisture, chemicals, or outdoor conditions. Plastic drums resist corrosion but often sacrifice structural integrity when subjected to impact or temperature extremes. Gorilla Drum™ offers durability without corrosion, maintaining its performance and structural stability across repeated use cycles. This reliability reduces product loss, minimizes downtime, and supports safer operations.

Efficiency is where Gorilla Drum™ truly separates itself from legacy solutions. Efficiency is not limited to shipping weight or purchase price; it encompasses the entire lifecycle of the drum. Gorilla Drum™ is engineered for efficient storage, handling, and reuse. Its consistent shape and construction support stable stacking and streamlined transport, helping organizations maximize space and reduce logistical friction. Over time, fewer replacements and less reconditioning lead to measurable cost savings and operational continuity.

Sustainability also plays a growing role in industrial decision-making. As companies work to reduce waste and extend product lifecycles, reusable and long-lasting drum solutions become increasingly valuable. Gorilla Drum™ supports these initiatives by offering a long service life that reduces material consumption and disposal compared to traditional drums that fail or degrade more quickly.

For organizations researching 55 gallon barrels for sale, the future is not found in repeating old choices. Investing in another steel drum or plastic barrel may solve an immediate need, but it does not address the broader operational challenges faced today. The smarter investment is a solution engineered for performance, efficiency, and longevity.

GORILLA DRUM™ is more than an alternative—it is a forward-looking approach to industrial drum solutions. By combining strength, durability, and efficiency without compromise, it sets a new standard for what storage drums and shipping drums should deliver in a modern industrial world.

Upgrade Your Drum Strategy

Whether you are currently relying on steel drums, industrial plastic drums, or evaluating alternatives to the traditional 55 gallon blue barrel, the drum solution you choose has a direct impact on your daily operations. From shipping efficiency and worker safety to storage capacity and long-term costs, drums play a critical role in how materials move through your organization. What may seem like a simple container decision can influence productivity, risk management, and overall operational performance.

Traditional steel drums have long been valued for their strength, but that strength comes at a cost. Excessive weight increases freight expenses, complicates handling, and contributes to workplace strain. Industrial plastic drums address some of these concerns by reducing weight and offering corrosion resistance, yet they often introduce new challenges, including vulnerability to cracking, deformation, or failure under repeated impact. For operations that depend on reliability and consistency, these compromises can lead to inefficiencies, product loss, and unplanned replacement costs.

GORILLA DRUM™ offers a smarter, stronger, and more efficient path forward. As the original steel drum alternative, it was engineered to eliminate the tradeoffs inherent in traditional drum designs. Gorilla Drum™ delivers the performance and durability expected from steel without the limitations of excessive weight, corrosion, or handling difficulty. At the same time, it provides the convenience and ease of use associated with plastic drums while maintaining superior impact resistance and long-term structural integrity.

Upgrading your drum strategy means looking beyond upfront pricing and evaluating total value. Gorilla Drum™ supports operational efficiency through reduced transportation costs, safer handling, and a longer service life. Its design is optimized for storage and shipping, helping organizations make better use of space and minimize logistical friction. Fewer replacements, fewer failures, and more consistent performance allow teams to focus on productivity rather than container-related issues.

Adopting Gorilla Drum™ also supports broader business goals. Improved durability and reuse align with sustainability initiatives by reducing waste and material consumption. Enhanced safety features contribute to a healthier work environment, while predictable performance supports compliance and quality standards across industries.

If you are ready to move beyond the limitations of traditional steel drums and plastic barrels, upgrading your drum strategy is a strategic step forward. GORILLA DRUM™ provides a proven, future-focused solution designed to meet the demands of modern industrial operations.

When performance matters and compromise is no longer acceptable, Gorilla Drum™ is ready to help you elevate your storage and shipping operations with the original steel drum alternative.

Call 800-758-8079 to speak with a drum solutions expert today, or download the Gorilla Drum Case Study by submitting our online form below to learn how GORILLA DRUM™ – The Original Steel Drum Alternative can transform your storage and shipping operations.

DOWNLOAD THE CASE STUDY

THIS IS JUST THE BEGINNING OF THE GORILLA DRUM™ STORY

Download the case study to get the full scoop.