Choosing the Best Drum Solution for Storage and Shipping Needs

Selecting the right drum for industrial operations is more than a matter of preference—it’s a strategic decision that impacts safety, cost, efficiency, and long-term operational performance. Whether your facility relies on 55 gallon drum containers, steel drums, or industrial plastic drums, understanding how different drum types affect storage, shipping, and handling is essential.

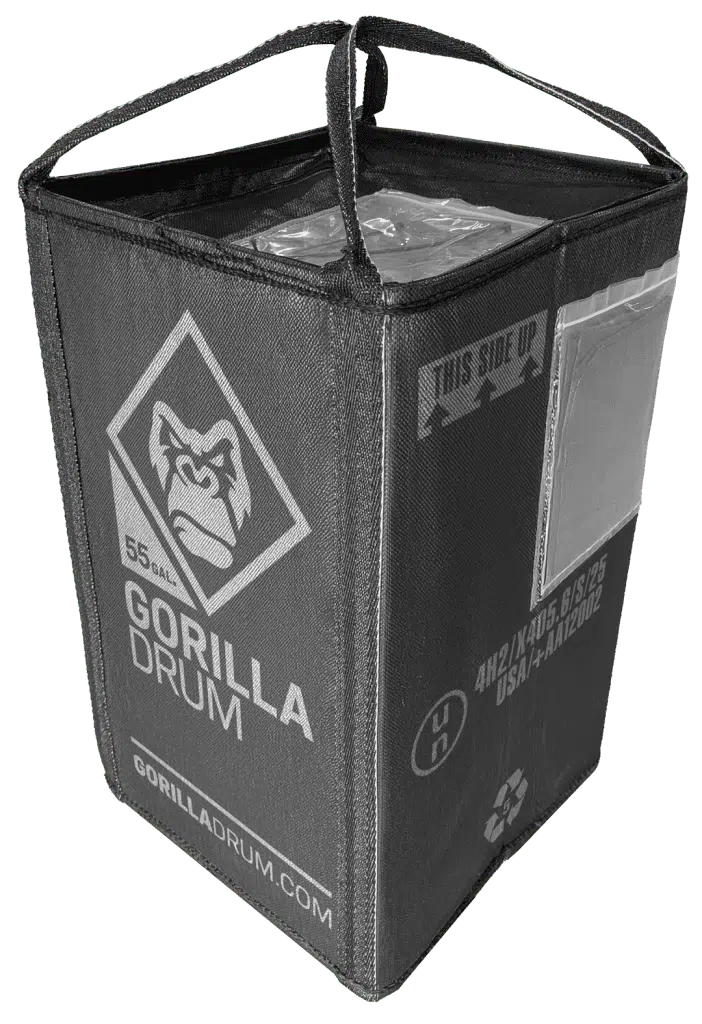

GORILLA DRUM™ – The Original Steel Drum Alternative offers a modern solution that balances the durability of traditional steel drums with the efficiency and versatility required in today’s industrial operations. This guide examines how to choose the best drum solution for your storage and shipping needs. For a more comprehensive overview, see our Essential Guide to 55-Gallon and Industrial Drum Solutions.

What Drum Type Minimizes Warehouse Space and Handling Costs?

Efficient warehouse operations require more than just well-organized shelving and optimized layouts—they depend on the design, weight, and stackability of the storage containers themselves. For businesses managing bulk liquids, chemicals, or industrial materials, the choice of storage drums directly affects labor costs, handling efficiency, and available warehouse space. Selecting a drum that balances durability with ease of handling can create significant operational savings over time.

Traditional Steel Drums

55 gallon steel drums have long been the standard in industrial applications. Their rugged construction allows them to withstand rough handling, heavy stacking, and demanding transport conditions. However, this strength comes at a cost. Steel drums are heavy even when empty, typically weighing around 40 pounds, and their weight increases dramatically when filled with liquids or dense materials.

The heavy nature of steel drums can slow warehouse operations, as more manpower or mechanical equipment is required for lifting, moving, and stacking. Handling strain on workers increases, and the risk of injury grows with repetitive manual tasks. Moreover, while steel drums can be stacked, their weight limits the stacking height to prevent structural damage, which reduces overall warehouse efficiency and usable space.

Industrial Plastic Drums

Industrial plastic drums, such as the common 55 gallon blue barrel, address some of the weight challenges associated with steel. They are lighter, corrosion-resistant, and easier to handle, which helps reduce labor costs and shipping expenses.

However, plastic drums have their own limitations in warehouse storage. When stacked under heavy loads, some plastic drums can deform, warp, or even crack over time. This limits stacking density and reduces the amount of material that can be stored in a given space. Facilities must also inspect plastic drums regularly to ensure they remain structurally sound, adding maintenance tasks and operational overhead.

Collapsible Drums

Collapsible drums were designed primarily to maximize logistical efficiency. Their foldable design allows empty drums to occupy minimal space during return shipping or storage, which can significantly reduce transportation costs and warehouse footprint.

While collapsible drums excel at saving space when empty, they can compromise durability when handling heavy or dense contents. Repeated folding and assembly cycles may weaken their structure, making them less suitable for high-stress industrial environments. Their limited stacking strength also restricts warehouse layout flexibility and may require additional safety precautions during storage.

Optimize Space and Handling

GORILLA DRUM™ – The Original Steel Drum Alternative was purpose-built to overcome the limitations of traditional steel, plastic, and collapsible drums. It combines the strength and stacking capability of steel with a lightweight design that reduces handling strain.

Key advantages of Gorilla Drum™ for warehouse efficiency include:

- Lightweight yet Durable Construction: Reduces manual handling effort and lowers risk of worker injury while supporting heavy loads.

- Optimized Stackability: Maintains structural integrity under repeated use, allowing higher stacking density and more efficient use of warehouse space.

- Ergonomic Design: Improves maneuverability, reducing labor costs associated with moving, lifting, and positioning drums.

- Long-Term Reliability: Durable construction minimizes the need for frequent replacements or repairs, ensuring consistent performance over time.

By combining these features, Gorilla Drum™ allows operations to maximize warehouse space without sacrificing durability or safety. Facilities can achieve higher storage efficiency, reduce labor and handling costs, and maintain reliable, long-term performance—making it a smarter investment than traditional steel drums, industrial plastic drums, or collapsible alternatives.

For businesses evaluating 55 gallon barrels for sale, choosing Gorilla Drum™ translates into measurable operational improvements and long-term cost savings, supporting both efficiency and productivity in demanding industrial environments.

How Do Different Drum Types Affect Shipping Weight and Fees?

Freight costs are a critical factor for any business that relies on storage drums or shipping drums to transport bulk materials. The type of drum chosen—steel, plastic, or collapsible—directly impacts shipping weight, labor requirements, and overall logistics expenses. Understanding these differences is essential for optimizing operational efficiency and reducing long-term costs.

Steel Drums and Shipping Weight

55 gallon steel drums are renowned for their durability and ability to handle heavy, dense contents, such as industrial chemicals, oils, and other bulk liquids. However, these benefits come at the cost of substantial weight. An empty steel drum typically weighs around 40 pounds, and a filled drum can exceed 1,000 pounds depending on the material inside.

This weight significantly influences freight costs. Carriers often charge based on weight or dimensional weight, meaning heavier drums translate directly into higher shipping fees. Additionally, handling these heavy containers requires forklifts, drum dollies, or additional personnel, further increasing labor and operational expenses. For companies shipping large volumes of steel drums, these costs can accumulate quickly, impacting profitability.

Industrial Plastic Drums

Industrial plastic drums, including the familiar 55 gallon blue barrel, offer a lighter alternative to steel. Their reduced weight makes them easier to handle manually and lowers overall freight costs. Plastic drums are particularly popular in industries where corrosion resistance is important, such as food processing or water storage, because they do not rust like steel.

However, plastic drums are less impact-resistant than steel. During transport, especially over long distances or through high-stress environments, plastic drums may crack, warp, or otherwise fail. This can lead to product loss, cleanup costs, and the need for drum replacement, which offsets some of the shipping cost savings. While lighter and easier to maneuver, plastic drums require careful handling and additional quality checks to maintain reliability.

Collapsible Drums

Collapsible drums provide an innovative solution for reducing empty return shipping and maximizing space efficiency. Their foldable design allows them to occupy minimal space when not in use, significantly lowering freight costs for empty drum returns.

However, collapsible drums have limitations when transporting full loads. Their foldable structure may not handle high stacking loads or repeated handling as well as steel or Gorilla Drum™, making them less suitable for long-term, high-stress shipping applications. Frequent transport of filled collapsible drums can compromise their durability, leading to additional costs in replacements or product loss.

How GORILLA DRUM™ Optimizes Shipping Efficiency

GORILLA DRUM™ – The Original Steel Drum Alternative was engineered to combine the best features of steel, plastic, and collapsible drums. It delivers the strength and durability of a 55 gallon steel drum while significantly reducing weight. This optimization reduces shipping fees by lowering freight weight, fuel consumption, and handling requirements.

In addition, Gorilla Drum™ maintains structural integrity under repeated handling, stacking, and long-distance transport, reducing the risk of product loss and the associated costs of replacement and cleanup. Its lighter weight also eases manual handling, decreasing labor strain and improving overall warehouse and shipping efficiency.

By balancing durability and weight, Gorilla Drum™ provides organizations with predictable shipping performance, lower freight costs, and long-term savings. Businesses evaluating 55 gallon drum containers or 55 gallon barrels for sale will find that Gorilla Drum™ represents a smarter, cost-effective choice for high-volume operations, combining operational efficiency with reduced risk and improved handling.

Which Drum Design Is Safest for Transporting Sensitive Materials?

Transporting sensitive or hazardous materials requires careful attention to container design, structural integrity, and material compatibility. Whether moving chemicals, industrial liquids, food-grade ingredients, or other sensitive products, the wrong drum can lead to leaks, spills, product loss, and safety hazards. Choosing the safest drum is critical for operational reliability, regulatory compliance, and overall workplace safety.

Steel Drums

55 gallon steel drums are widely recognized for their strength and puncture resistance, making them a traditional choice for transporting dense or heavy materials. Their robust construction allows them to withstand impact, stacking loads, and harsh handling conditions.

However, steel drums are not without limitations. Over time, steel can corrode, particularly when exposed to reactive chemicals, water, or humid environments. Corrosion compromises structural integrity and increases the risk of leaks or contamination. Additionally, steel drums are heavy, which makes handling more difficult and can increase the likelihood of accidents or spills if not managed carefully. For sensitive materials, these factors create potential safety and operational risks despite the drum’s inherent strength.

Industrial Plastic Drums

Industrial plastic drums, such as the common 55 gallon blue barrel, offer corrosion resistance and reduced weight compared to steel. Their chemical-resistant construction makes them suitable for transporting a variety of industrial and food-grade liquids. Lighter weight also makes them easier to handle manually, reducing labor strain and minimizing handling errors.

However, plastic drums are vulnerable to cracks, warping, or stress fractures under repeated impacts, extreme temperatures, or heavy stacking loads. Any compromise in the drum’s integrity can result in spills, contamination, or product loss. While plastic drums are convenient and lightweight, their reliability in high-impact or extreme conditions is limited, which may make them less ideal for highly sensitive or hazardous materials.

Collapsible Drums

Collapsible drums were primarily designed for space efficiency and return shipping of empty containers. Their foldable construction allows them to occupy minimal space, reducing storage and freight costs.

Despite these advantages, collapsible drums are generally less suitable for transporting sensitive materials. The foldable design can compromise durability under heavy loads, repeated handling, or long-distance transport. Collapsible drums are more prone to deformation, structural weakening, and potential failure, particularly when filled with dense or reactive substances. While they are efficient for logistics, they may not provide the consistent reliability needed for safe transport of sensitive materials.

How GORILLA DRUM™ Ensures Safe Transport

GORILLA DRUM™ – The Original Steel Drum Alternative was engineered to meet the unique challenges of transporting sensitive materials. It combines the strength and impact resistance of a steel drum with the lightweight design and chemical compatibility of advanced industrial materials.

Key safety features of Gorilla Drum™ include:

- Impact-Resistant Construction: Protects contents during handling, stacking, and transit, reducing the risk of spills or damage.

- Structural Stability: Maintains integrity under repeated use and heavy loads, ensuring reliable performance in demanding industrial environments.

- Chemical Compatibility: Suitable for a wide range of industrial, chemical, and food-grade materials, preventing contamination and corrosion.

- Lightweight Design: Easier to handle than steel drums, reducing the risk of worker injury and accidental drops.

By providing a reliable, durable, and safe container, Gorilla Drum™ minimizes operational risk while transporting sensitive or hazardous materials. Organizations can reduce product loss, improve workplace safety, and maintain regulatory compliance with a container designed specifically for industrial performance.

For companies evaluating 55 gallon drum containers or 55 gallon barrels for sale, Gorilla Drum™ offers a safer, more predictable option than traditional steel, plastic, or collapsible drums. Its engineered design ensures that sensitive materials are transported securely, efficiently, and with confidence—making it the optimal choice for modern industrial operations.

Why Gorilla Drum™ Is the Optimal Choice

Choosing the right drum affects every stage of industrial operations—from storage and handling to shipping and long-term cost management. Traditional steel drums, plastic drums, and collapsible drums each have advantages, but also limitations in weight, durability, and operational efficiency.

GORILLA DRUM™ – The Original Steel Drum Alternative bridges these gaps by offering:

- Strength and impact resistance comparable to steel drums

- Reduced weight for safer handling and lower freight costs

- Long service life that minimizes replacement and downtime

- Efficient stacking and warehouse storage for optimized space utilization

- Safe transport for sensitive or hazardous materials

For organizations investing in 55 gallon drum containers, Gorilla Drum™ provides a modern solution that meets the demands of today’s industrial operations. It improves cost-efficiency, supports sustainability goals through reuse, and enhances safety across storage and shipping processes.

Ready to improve your drum strategy? Call 800-758-8079 to speak with a drum solutions expert today, or submit our online form below to download the Gorilla Drum Case Study and learn how GORILLA DRUM™ can optimize your storage, shipping, and industrial drum needs.

DOWNLOAD THE CASE STUDY

THIS IS JUST THE BEGINNING OF THE GORILLA DRUM™ STORY

Download the case study to get the full scoop.