Steel, Plastic, and Collapsible Drums: Key Differences

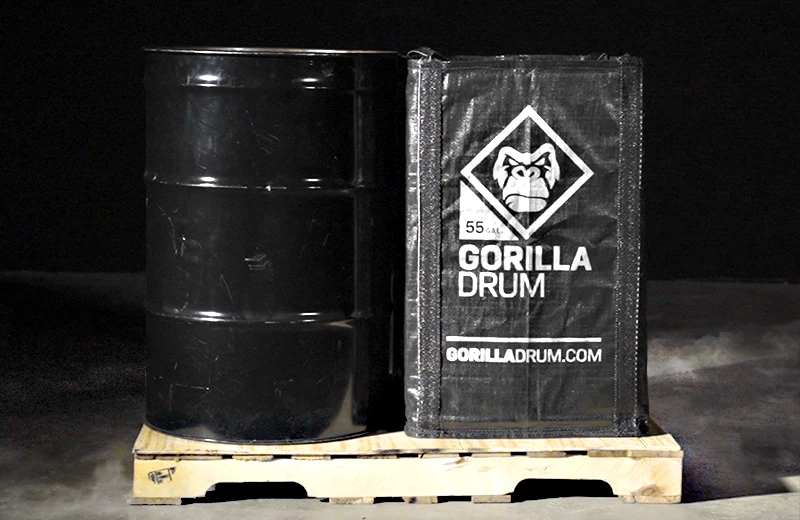

The 55 gallon drum has long been a cornerstone of industrial storage and shipping. Across manufacturing, chemical processing, agriculture, and logistics, these containers provide a standardized solution for handling bulk materials. Traditionally, steel drums dominated rugged applications, while industrial plastic drums—often recognized as the familiar 55 gallon blue barrel—offered a lighter, corrosion-resistant alternative. Collapsible drums emerged more recently to address efficiency and space challenges in logistics.

While each type of drum has its place, modern industrial operations increasingly demand solutions that balance durability, weight, cost, and long-term performance.

GORILLA DRUM™ – The Original Steel Drum Alternative was engineered to meet these demands, combining the strength of steel with the convenience and efficiency of advanced drum designs. This guide explores the key differences between steel, plastic, and collapsible drums and provides insight into how organizations can select the right solution for their needs. For a deeper dive into the broader context of industrial drum solutions, see our Essential Guide to 55-Gallon and Industrial Drum Solutions.

How Heavy Is a 55 Gallon Steel Drum?

Understanding the weight of a drum is a fundamental consideration for industrial operations, impacting shipping costs, handling requirements, and workplace safety. The 55 gallon drum is one of the most common industrial containers, and its weight plays a critical role in how it is stored, transported, and used in manufacturing, chemical, agricultural, and logistics applications.

Empty Weight

A standard 55 gallon steel drum is constructed from thick, durable metal designed to withstand repeated impacts, heavy stacking, and the rigors of industrial transport. The empty weight of a steel drum typically falls around 40 pounds. While manageable in controlled conditions or when mechanical handling equipment is used, repeated manual handling can quickly lead to worker fatigue and increase the risk of strain or injury. In facilities where hundreds or thousands of drums are handled regularly, the cumulative effect of lifting and moving steel drums becomes a significant operational consideration.

Filled Weight

The weight of a steel drum increases dramatically once it is filled. The total weight depends on the density of the material contained within the drum. For example:

- Water: A 55 gallon steel drum filled with water weighs approximately 500 pounds.

- Oils or dense chemicals: Depending on their density, filled drums can easily exceed 1,000 pounds.

- Powders or lighter liquids: These may result in a filled drum weight closer to 600–700 pounds.

This considerable weight requires mechanical handling equipment, such as forklifts, pallet jacks, or drum dollies, to ensure safe transport and storage. Additionally, heavier drums significantly increase freight costs, fuel consumption, and labor requirements, adding to overall operational expenses.

Comparison to Plastic and Collapsible Drums

Industrial plastic drums are a lighter alternative to steel, with empty weights typically ranging from 20–30 pounds. Even when filled, plastic drums are easier to maneuver than their steel counterparts, making them a popular choice for applications where weight reduction and corrosion resistance are priorities.

Collapsible drums take weight reduction and efficiency a step further. Their foldable design drastically reduces shipping and storage volume when empty, which lowers transportation costs and improves return logistics. However, traditional collapsible drums may not provide the same level of durability or structural integrity under heavy loads compared to steel drums.

How GORILLA DRUM™ Improves Efficiency

While steel drums deliver strength and durability, their weight remains a practical limitation in modern industrial operations. GORILLA DRUM™ – The Original Steel Drum Alternative addresses this challenge by offering comparable strength to a 55 gallon steel drum while significantly reducing weight. The engineered design maintains structural integrity under heavy loads, repeated handling, and stacking, while minimizing strain on workers and reducing shipping and handling costs.

By combining durability, lighter weight, and optimized ergonomics, Gorilla Drum™ improves overall efficiency without compromising performance, making it a superior choice for storage drums, shipping drums, and industrial operations where both safety and cost-effectiveness are critical.

How Do Steel, Plastic, and Collapsible Drums Perform Under Stress?

Industrial operations place storage drums and shipping drums under considerable stress. These containers are expected to withstand repeated handling, heavy stacking loads, temperature fluctuations, impacts during transport, and the wear and tear of day-to-day use. Selecting the right type of drum is critical to maintaining operational efficiency, worker safety, and the integrity of the materials being stored or shipped.

Steel Drums

Steel drums have long been the standard for rugged industrial applications. Their thick, durable metal construction allows them to carry heavy contents, endure rough handling, and support high stacking loads without immediate failure. They are especially valuable for transporting dense liquids, chemicals, oils, and industrial byproducts.

However, steel drums are not without limitations. Over time, they are susceptible to dents, deformation, and corrosion, particularly in harsh environments or when exposed to moisture and chemicals. Their weight also presents challenges—manual handling can increase the risk of strain or injury, and additional mechanical equipment may be needed to safely move filled drums. Regular inspection and maintenance are necessary to ensure long-term reliability, which adds to labor and operational costs.

Industrial Plastic Drums

Industrial plastic drums offer an alternative that addresses some of the weight and corrosion concerns associated with steel. Plastic drums are lighter and resistant to rust, making them suitable for certain chemical, food-grade, or water-based applications. Their reduced weight lowers shipping costs and allows easier manual handling compared to steel.

However, plastic drums introduce their own vulnerabilities. They are more prone to cracking, warping, or developing stress fractures when subjected to repeated impacts, extreme temperatures, or heavy stacking. Over time, this can reduce their service life and increase the risk of leaks or product loss. While cost-effective and easier to transport, plastic drums may not provide the consistent durability needed for demanding industrial environments.

Collapsible Drums

Collapsible drums were developed primarily for logistical efficiency. Their foldable design allows empty drums to occupy minimal space during return shipping, lowering freight and storage costs. This makes them appealing for businesses that frequently return empty drums for reuse or recycling.

Despite these advantages, collapsible drums are less durable under stress than steel or Gorilla Drum™. They may not handle high stacking loads well, and repeated assembly and collapse cycles can weaken the structure over time. They are generally less suitable for transporting dense materials or withstanding high-impact conditions, limiting their use in demanding industrial applications.

GORILLA DRUM™ – Performance Under Stress

GORILLA DRUM™ – The Original Steel Drum Alternative was engineered to address the limitations of all three traditional drum types. It combines the strength and stacking ability of steel drums with the lightweight, impact-resistant characteristics of advanced industrial materials.

GORILLA DRUM™ maintains structural integrity under repeated handling, stacking, and transport. Its optimized design supports heavy loads while reducing worker strain and lowering transportation costs. Unlike plastic or collapsible drums, it can withstand harsh industrial conditions without cracking, warping, or failing, making it a reliable and cost-effective solution for long-term use.

For industrial operations seeking storage drums and shipping drums that can consistently perform under stress, Gorilla Drum™ offers the ideal balance of strength, durability, and efficiency, setting a new standard for modern drum solutions.

What Are the Differences Between Steel and Collapsible Drums?

Steel and collapsible drums represent two distinct approaches to industrial storage, each designed to meet specific operational priorities. Understanding their differences is essential for companies seeking the most effective solution for shipping, storage, and handling of bulk materials. While steel drums prioritize rugged durability, collapsible drums focus on efficiency and space savings. However, both come with inherent trade-offs that can affect long-term performance and operational costs.

Steel Drums

Steel drums have long been the gold standard for industrial storage and shipping due to their strength and durability. They are constructed from thick, heavy-duty metal, allowing them to withstand rough handling, high stacking loads, and long-distance transport. This makes them ideal for dense materials, hazardous liquids, chemicals, oils, lubricants, and industrial byproducts.

Key characteristics of steel drums include:

- Exceptional Durability: Steel drums resist punctures, crushing, and deformation, making them suitable for high-stress environments.

- High Stacking and Load Capacity: Their structural integrity allows multiple drums to be stacked safely, maximizing warehouse space and enabling efficient transport.

- Heavy Weight: While their robustness is a major advantage, steel drums are heavy, even when empty. A standard 55 gallon steel drum weighs approximately 40 pounds, and when filled, the total weight can exceed 500–1,000 pounds depending on the material. This increases the strain on workers and necessitates mechanical handling equipment, which can elevate labor costs.

- Susceptibility to Corrosion and Wear: Over time, steel drums can rust, dent, or otherwise degrade, especially in outdoor or corrosive environments. Regular inspection and maintenance are required to ensure safe long-term use.

Steel drums are reliable and rugged, but their weight, handling demands, and maintenance requirements can pose challenges for modern operations that value efficiency and cost-effectiveness.

Collapsible Drums

Collapsible drums were developed to address a different set of priorities, primarily logistics and space efficiency. Their foldable design allows them to occupy minimal space when empty, which reduces return shipping costs and storage requirements. These drums are often lightweight and easy to maneuver, making them attractive for companies that ship large volumes of empty containers back to the origin or reuse them frequently.

Key characteristics of collapsible drums include:

- Logistical Efficiency: Collapsible drums minimize empty-space transportation costs and improve warehouse space utilization.

- Lightweight Construction: Their reduced weight makes manual handling easier and decreases overall shipping costs compared to steel drums.

- Lower Durability: Collapsible drums are generally less capable of handling high stacking loads or repeated high-impact scenarios. Repeated assembly and collapse cycles can weaken the structure over time, increasing the risk of deformation or failure.

- Limited Lifespan in Harsh Environments: While efficient for transport and storage, collapsible drums may not withstand the demanding conditions often encountered in industrial operations, particularly with heavy, dense, or hazardous contents.

How GORILLA DRUM™ Bridges the Gap

GORILLA DRUM™ (The Original Steel Drum Alternative) was engineered to provide the best of both worlds. It combines the strength, load-bearing capacity, and impact resistance of steel drums with the lighter weight, efficiency, and ease of handling typically associated with collapsible or plastic designs.

Unlike traditional steel drums, Gorilla Drum™ reduces handling strain and lowers transportation costs while maintaining exceptional durability. Unlike collapsible drums, it can reliably support heavy loads, endure repeated handling, and maintain structural integrity in demanding industrial applications.

GORILLA DRUM™ is designed for long-term use, reducing replacement frequency and minimizing operational disruptions. Its optimized design supports efficient stacking, safe transport, and versatile applications across industries, from chemicals and oils to food ingredients and environmental materials.

By bridging the gap between traditional steel and collapsible drums, Gorilla Drum™ offers a modern, high-performance solution that meets the evolving needs of industrial operations. For businesses seeking storage drums, shipping drums, or industrial drums that deliver both strength and efficiency, Gorilla Drum™ provides a superior alternative that balances durability, cost-effectiveness, and operational practicality.

Choosing the Right Drum for Your Operations

When evaluating 55 gallon drum containers or 55 gallon barrels for sale, decision-makers should consider multiple factors:

- Weight and handling requirements

- Environmental conditions and chemical compatibility

- Expected impact and stacking loads

- Frequency of reuse and lifecycle costs

- Transportation and storage efficiency

GORILLA DRUM™ simplifies this decision by combining the advantages of traditional steel drums with the efficiency and durability of modern drum alternatives. Its long service life, optimized weight, and engineered strength make it a superior choice for industrial drums, shipping drums, and storage drums.

Steel, plastic, and collapsible drums each have unique advantages and limitations. Understanding their differences is essential for selecting the right solution for your storage and shipping needs. While steel offers traditional strength, and collapsible designs offer logistical efficiency, GORILLA DRUM™ – The Original Steel Drum Alternative provides a modern solution that delivers strength, durability, and efficiency without compromise.

Ready to upgrade your drum transport strategy? Gorilla Drum™ is ready to help. Call 800-758-8079 to speak with a drum solutions expert today, or submit our online form below to download the Gorilla Drum Case Study and learn how GORILLA DRUM™ can optimize your storage, shipping, and operational performance.

DOWNLOAD THE CASE STUDY

THIS IS JUST THE BEGINNING OF THE GORILLA DRUM™ STORY

Download the case study to get the full scoop.