For companies relying on 55-gallon steel drums for their packaging and waste hauling, the last few years have exposed a handful of challenges. Supply chain disruptions, increased steel prices, and decreased availability of the raw materials to produce new 55-gallon drums have made it difficult for companies to maintain consistent productivity.

For companies relying on 55-gallon steel drums for their packaging and waste hauling, the last few years have exposed a handful of challenges. Supply chain disruptions, increased steel prices, and decreased availability of the raw materials to produce new 55-gallon drums have made it difficult for companies to maintain consistent productivity.

What’s more, fuel cost increases and the continued push for more sustainable business practices have made steel drums less cost-effective and less viable, leading to the need for a more sustainable packaging solution.

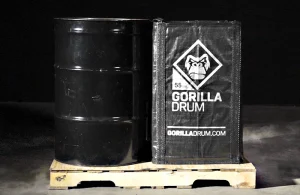

As a more flexible, eco-friendly 55-gallon steel drum alternative, Gorilla Drum™ can help companies eliminate the monkeying around that comes with using traditional drums, and adopt a more streamlined, sustainable approach to packaging and logistics. Here, we’ll look at five unique features that make Gorilla Drum™ the ideal solution to optimize efficiency and help save you time and money.

Gorilla Drum™ uses a plastic, fully collapsible frame

There’s nothing flexible about 55-gallon steel drums. They take up a ton of square footage in your warehouse, and you can only fit so many units on a pallet. Plus, the sheer weight and cylindrical shape of steel drums makes them difficult to palletize and transport.

Gorilla Drum™ utilizes a corrugated, polypropylene frame that is fully collapsible to help you fit 80 units per pallet. This flexible frame design helps reduce the amount of warehouse space necessary to store unfilled units, and the lightweight engineering makes it faster and easier to transport units around your facility. What’s more, a 100% recyclable woven plastic frame makes Gorilla Drum™ a more eco-friendly packaging solution to help meet your sustainability initiatives.

With Gorilla Drum™, you can reduce your FTLs by fitting more units on a truck

Reducing the number of FTLs required to meet your packaging and shipping needs is a key piece in optimizing a variety of freight expenses like fuel costs or fleet maintenance. This means companies in high-volume industry applications like hazmat and non-hazmat waste hauling experience significant challenges in controlling these costs because of the large number of FTLs required to meet demand.

Standard trucks with a capacity of 52 pallets can accommodate just 208 steel drums. However, Gorilla Drum™’s flexible engineering makes it possible to fit 4,160 collapsed units on a standard truck to significantly reduce your FTLs to help optimize your freight costs and reduce your carbon footprint — fewer trucks on the road means less fuel consumption and reduced carbon emissions.

The ability to fit 20x more units on a standard 53-foot truck also makes it easier to scale your waste hauling, packaging, and transportation logistics based on customer demand.

Gorilla Drum™ helps you lose the weight of steel drums — and keep it off for good

The average weight of an unfilled 55-gallon steel drum is between 48 to 80 lbs. The base weight of steel drums makes them difficult to transport around a facility, and it also presents a safety hazard to your warehouse staff in the event a drum is dropped or mishandled. Additionally, drums on the higher end of the weight range may require multiple people or specialized equipment to transport safely.

An unfilled Gorilla Drum™ weighs just 7.5 lbs. The fully collapsible frame makes it easy to stack multiple drums on a standard pallet, and the lightweight design decreases the potential for workplace accidents.

However, just because Gorilla Drum™ is lightweight in design, that doesn’t mean it’s lightweight in terms of performance. Rated X for Packing Groups I, II, and II, our steel drum alternative is UN and DOT certified with a weight capacity of 452 lbs and a 6:1 safety factor.

Gorilla Drum™ is a total breeze to set up and transport

A common refrain in favor of traditional 55-gallon steel drums is that they require very little setup time. However, transporting steel drums — even unfilled drums — can be a time-intensive process that requires multiple warehouse personnel or special equipment outside of a standard forklift.

Preparing Gorilla Drum™ for packaging and transportation can be completed in just a handful of steps without the need for specialized tools or equipment. A removable inner liner and zipper lid provides superior protection for hazmat and non-hazmat solids, and the polypropylene frame offers high levels of performance and durability in the event the unit is dropped or knocked over.

Our focus on the speed, ease, and safety of transporting a filled Gorilla Drum™ is demonstrated by UN-rated lifting straps, a flexible belly band, and dolly straps. These design features make it possible for units to be moved via warehouse staff, dolly, or forklift depending on the weight and contents of the unit.

Gorilla Drum™ can be used for a variety of industry applications

Part of what makes Gorilla Drum™ more efficient than traditional 55-gallon steel drums is its capacity to be used in a variety of industry applications without alterations or modifications. What’s more, the disposable inner liner makes it fast and simple to repurpose the unit for use without the intense and costly cleaning of steel drums.

A standard Gorilla Drum™ unit can be used in applications such as:

- Waste hauling and disposal — haz and non-haz solids

- Lab packs — laboratories, hospitals, and universities

- Medical/healthcare packaging and transportation

- B2B shipping/packaging

- Sustainable packaging

With Gorilla Drum™, you not only unlock a more efficient, cost-effective, and sustainable packaging and transportation solution, but you can more easily navigate the jungle that is growing your business.

Want to learn how Gorilla Drum™ helped a global package handler save time and money by conserving warehouse space and streamlining waste hauling processes? Download our new case study to read the full story.