What Drum Type Minimizes Warehouse Space and Handling Costs?

For industrial operations, selecting the right 55 gallon drum is more than a matter of choosing a container—it directly impacts warehouse efficiency, labor costs, and overall operational performance. Whether you’re using storage drums, shipping drums, or 55 gallon drum containers, understanding how different drum types affect space utilization and handling can lead to substantial savings and improved workflow.

For a detailed guide on choosing the right drum for your operation, see Choosing the Best Drum Solution for Storage and Shipping Needs.

Traditional Steel Drums: Strength Comes With Limitations

Steel drums, particularly the standard 55 gallon steel drum, have long been the backbone of industrial storage. Their thick metal construction provides excellent durability and load-bearing capacity, making them ideal for dense materials, hazardous liquids, and high-impact shipping scenarios.

However, steel drums carry notable operational drawbacks:

- Weight: An empty steel drum typically weighs around 40 pounds, and filled drums can exceed 1,000 pounds depending on the material. This weight increases labor strain and requires forklifts or drum dollies for safe handling.

- Handling Costs: Heavy steel drums are more difficult to maneuver manually, increasing labor requirements and the potential for workplace injuries.

- Warehouse Space: Steel drums require careful stacking to avoid damage or tipping. Their weight and rigidity can limit stacking density and reduce overall warehouse efficiency.

While steel drums excel in strength and reliability, their limitations in handling and storage efficiency make them less suitable for operations seeking to maximize warehouse space and reduce labor costs.

Industrial Plastic Drums: Lighter but Less Durable

Industrial plastic drums, including the familiar 55 gallon blue barrel, provide a lighter alternative to steel. Empty plastic drums typically weigh between 20–30 pounds, making them easier to move manually and reducing shipping costs. They are corrosion-resistant and suitable for a range of chemical and food-grade applications.

Plastic drums offer some advantages in warehouse efficiency:

- Reduced weight: Easier to handle and move, lowering labor costs.

- Stacking potential: Light weight allows moderate stacking density without heavy mechanical equipment.

However, plastic drums have limitations in demanding industrial conditions:

- Durability concerns: They may crack, warp, or deform under heavy loads or repeated stacking.

- Reduced lifespan: In high-impact or industrial environments, plastic drums may need replacement sooner than steel, increasing operational costs.

While they improve handling and reduce labor strain, plastic drums may not fully optimize warehouse space if stacking limitations prevent high-density storage.

Collapsible Drums: Efficiency With Trade-Offs

Collapsible drums were designed to maximize efficiency during return shipping and storage. Their foldable design allows empty drums to occupy minimal space, reducing freight costs and storage requirements.

Key advantages include:

- Space savings: Collapsible drums can be folded down when empty, freeing up valuable warehouse space.

- Lightweight design: Easier to handle and transport than steel drums.

However, collapsible drums also have significant drawbacks:

- Lower structural integrity: They may not support heavy contents or repeated stacking as reliably as steel or Gorilla Drum™ alternatives.

- Durability over time: Repeated assembly and collapse cycles can weaken the structure, reducing service life.

- Limited application: Collapsible drums are not ideal for long-term storage of dense or high-impact materials.

While they excel in reducing return shipping volume, collapsible drums do not always provide the durability and reliability needed for industrial operations under heavy use.

GORILLA DRUM™: Optimizing Space and Handling

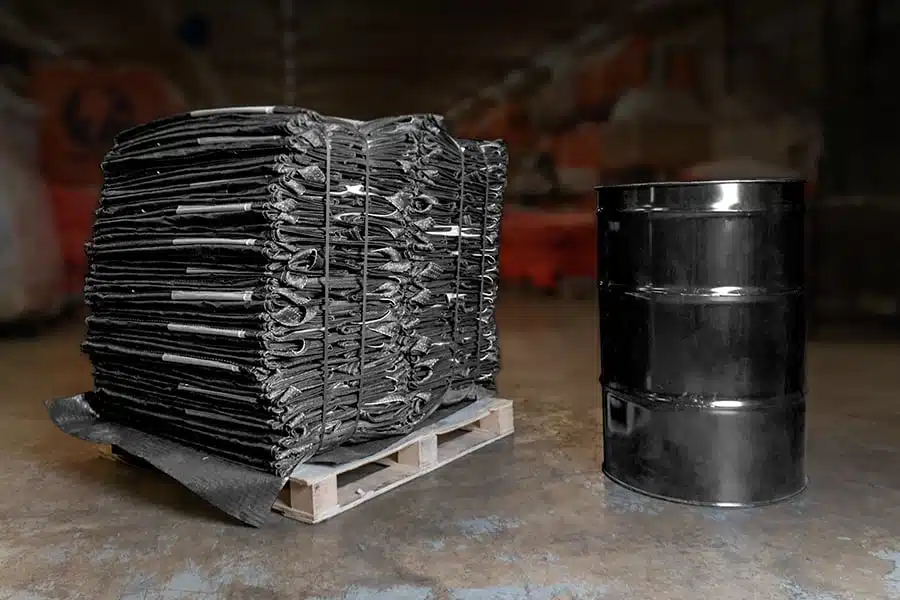

GORILLA DRUM™ – The Original Steel Drum Alternative bridges the gap between strength and efficiency. It is engineered to provide the performance of a 55 gallon steel drum while eliminating many of the operational drawbacks associated with traditional drums.

Benefits of Gorilla Drum™ include:

- Lightweight construction: Easier to handle than steel drums, reducing labor strain and improving warehouse ergonomics.

- Durability: Engineered to withstand repeated stacking, transport, and industrial use without deformation or compromise.

- Stacking efficiency: The optimized design allows for safer, higher-density stacking, maximizing warehouse space.

- Operational cost savings: Reduced handling difficulty, lower shipping fees, and minimized replacement needs lead to measurable savings over time.

GORILLA DRUM™ is ideal for companies evaluating 55 gallon barrels for sale or looking to optimize industrial drums for warehouse efficiency and handling costs.

Making the Right Choice for Your Warehouse

When selecting a 55 gallon drum container, consider the following factors to maximize warehouse efficiency and reduce operational costs:

- Weight: Lighter drums improve handling and reduce labor costs.

- Stackability: Durable, high-strength drums allow for higher stacking density.

- Durability: Choose drums that withstand repeated use, heavy loads, and transport impacts.

- Long-term savings: Factor in handling, shipping, and replacement costs, not just initial purchase price.

By selecting Gorilla Drum™, organizations can optimize warehouse layout, minimize labor strain, and achieve predictable performance across industrial operations.

When evaluating drum options, the impact on warehouse space and handling costs is critical. Traditional steel drums are strong but heavy and limit stacking density. Industrial plastic drums are lighter and easier to handle but may deform under heavy loads. Collapsible drums save space during return shipping but can lack durability in industrial environments.

GORILLA DRUM™ combines the best of all worlds: strength comparable to steel, lightweight handling, impact resistance, and long-term durability. For businesses seeking high-performance storage drums, industrial drums, or shipping drums, Gorilla Drum™ provides the optimal solution for efficiency, safety, and cost-effectiveness.

For a complete guide on selecting the right industrial drum, visit the Essential Guide to 55-Gallon and Industrial Drum Solutions.

Call 800-758-8079 or submit our online form below to learn how Gorilla Drum™ can transform your storage and shipping operations.

DOWNLOAD THE CASE STUDY

THIS IS JUST THE BEGINNING OF THE GORILLA DRUM™ STORY

Download the case study to get the full scoop.

DOWNLOAD THE CASE STUDY

THIS IS JUST THE BEGINNING OF THE GORILLA DRUM™ STORY

Download the case study to get the full scoop.