Selecting the right container for hazardous waste isn’t just a matter of convenience—it’s a matter of safety, compliance, and environmental responsibility. Every organization that handles, stores, or transports hazardous materials must use containers designed and tested to meet stringent industry and regulatory standards. Choosing the wrong drum can lead to spills, contamination, or costly violations.

Selecting the right container for hazardous waste isn’t just a matter of convenience—it’s a matter of safety, compliance, and environmental responsibility. Every organization that handles, stores, or transports hazardous materials must use containers designed and tested to meet stringent industry and regulatory standards. Choosing the wrong drum can lead to spills, contamination, or costly violations.

Hazmat drums are the backbone of safe hazardous waste management. Whether handling chemical liquids, contaminated solids, or reactive materials, these drums provide the containment integrity necessary to prevent leaks and protect the environment. But with multiple materials, sizes, and certification types available, understanding which drum is right for your specific application can be complex.

This comprehensive guide explores how to choose the right hazmat drums for waste storage. It covers how UN and DOT ratings impact safety and compliance, the best practices for storing and transporting chemical waste, and the different 55 gallon drum options available for hazardous material disposal.

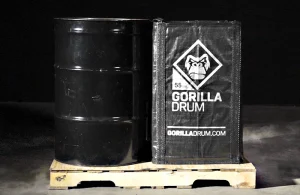

Gorilla Drum provides industry-leading containment solutions that redefine waste management—lightweight, reusable, collapsible designs that meet all performance and compliance standards while helping organizations reduce storage costs and environmental impact.

Understanding the Importance of Hazmat Drums

Hazmat drums are specially designed containers used for the storage and transport of hazardous materials. These can include flammable liquids, corrosive chemicals, toxic substances, and regulated industrial waste. Their design ensures that materials are securely sealed to prevent leaks, spills, or vapor release.

A 55 gallon hazmat drum remains one of the most common container sizes, widely used for its versatility and compatibility with industrial handling systems. These drums are made from steel, plastic, or composite materials and are tested for durability, chemical resistance, and load capacity.

UN rated hazmat drums and DOT approved hazmat containers guarantee that a drum has passed rigorous performance testing, making them compliant for use across multiple industries. Choosing containers with these certifications ensures adherence to safety laws and transport regulations both domestically and internationally.

Key Considerations When Choosing a Hazmat Drum

When selecting a drum for hazardous waste, several factors influence the right choice:

-

Type of material: Whether the waste is liquid, solid, or sludge affects the choice of drum material and closure type.

-

Chemical compatibility: The drum must resist corrosion or chemical reaction with the contents.

-

Regulatory requirements: UN and DOT ratings must match the hazard classification of the waste.

-

Handling and storage needs: Size, weight, and stacking ability impact efficiency in storage and transport.

-

Sustainability and reusability: Reusable drums reduce waste generation and overall cost.

With these elements in mind, let’s explore each key area in more depth.

Understanding UN And DOT Ratings For Hazmat Drums

Every organization that handles or transports hazardous materials must understand the difference between UN and DOT ratings. These standards are not optional—they’re essential to ensuring safety, legal compliance, and environmental protection. Each rating system provides its own set of criteria that a container must meet before it can be used for hazardous waste or chemical storage.

Every organization that handles or transports hazardous materials must understand the difference between UN and DOT ratings. These standards are not optional—they’re essential to ensuring safety, legal compliance, and environmental protection. Each rating system provides its own set of criteria that a container must meet before it can be used for hazardous waste or chemical storage.

A UN rated hazmat drum or DOT approved hazmat container doesn’t just signify quality—it demonstrates that the container has undergone extensive testing to prove its reliability under extreme conditions. Choosing the correct rating ensures that every drum used in your facility aligns with the specific type of material being stored or transported.

The Purpose of UN Ratings

The United Nations developed the UN Recommendations on the Transport of Dangerous Goods—often called the “Orange Book”—to create a universal standard for packaging and labeling hazardous substances. This system ensures that a drum certified in one country can be legally and safely transported in another without the need for retesting or recertification.

When you see a UN code printed on a hazmat barrel, it serves as a global passport for compliance. These markings verify that the container meets international performance-based testing standards for impact resistance, stacking strength, and leakproofness.

For example, a 55 gallon hazmat drum may carry a UN code such as “UN 1H1/Y1.9/200/25/USA/M4567.” Here’s what each part of that marking means:

-

UN – Indicates certification under United Nations regulations.

-

1H1 – Identifies the drum type (plastic, closed head).

-

Y – Denotes its suitability for medium hazard materials (Packing Group II).

-

1.9 – Refers to the specific gravity of the material it can safely hold.

-

200 – Indicates hydrostatic test pressure in kilopascals (kPa).

-

25 – Year of manufacture.

-

USA/M4567 – Country and manufacturer identification.

Each element of the code confirms that the container was designed, tested, and certified for a specific range of hazards. These ratings prevent incompatible materials from being stored in unsuitable containers—reducing the risk of rupture, corrosion, or chemical reaction.

The Role of DOT Ratings

While the UN system governs international standards, the U.S. Department of Transportation (DOT) oversees domestic transport safety under Title 49 of the Code of Federal Regulations (CFR). A DOT approved hazmat container must meet performance standards that ensure it can withstand the rigors of real-world handling and transportation.

DOT testing includes:

-

Drop tests from specified heights to simulate accidental falls.

-

Leakproofness tests to confirm the integrity of closures and seams.

-

Hydrostatic pressure tests for internal pressure resistance.

-

Vibration and stacking tests to ensure durability during long-distance shipping.

A drum that passes all of these tests earns DOT certification, which allows it to be legally used within the United States for the transport of hazardous waste, chemicals, and regulated materials.

The Relationship Between UN and DOT Standards

Although they are separate systems, UN and DOT regulations complement one another. Most drums used in modern waste management and chemical industries carry both UN and DOT markings. This dual compliance ensures that the same container can be used for domestic transport, international shipping, and long-term hazardous waste storage.

In practice, this means a company can purchase a single type of certified drum and use it confidently across all operations, minimizing confusion and ensuring seamless compliance.

Why These Ratings Are Critical for Compliance and Safety

The importance of certification goes far beyond meeting paperwork requirements. UN and DOT ratings directly impact worker safety, environmental protection, and cost efficiency. Containers that lack these certifications can fail under pressure, leading to hazardous spills, regulatory fines, and reputational damage.

Using UN rated hazmat drums and DOT approved hazmat containers guarantees that your materials are stored in compliance with both international and federal standards. This ensures peace of mind that the containers will perform under extreme temperature shifts, handling stress, and prolonged storage conditions.

Common Misconceptions About Drum Ratings

Many organizations mistakenly assume that all 55 gallon drums are suitable for hazardous materials. However, not all drums are created equal. A drum designed for food or non-hazardous liquids may not meet the same standards as a hazardous waste drum. Only certified hazmat storage drums that carry valid UN and DOT markings are approved for regulated waste.

Another misconception is that once a drum has been certified, it remains compliant indefinitely. In reality, both the drum and its certification are subject to periodic inspection. Damage, corrosion, or unauthorized modification can void compliance. For this reason, every drum should be checked for visible wear, proper labeling, and legible certification markings before each use.

Integrating Certified Drums Into Your Waste Management Plan

Facilities that store or transport chemicals must document their use of certified containers as part of their environmental compliance plan. This includes keeping track of the manufacturer’s specifications, the intended use of the drum, and inspection logs.

Working with a trusted supplier like Gorilla Drum ensures every container you use is properly certified and tested to meet the latest UN and DOT standards. With Gorilla Drum’s advanced designs and reliable certification, your operation remains compliant, efficient, and environmentally responsible.

Understanding these regulations—and implementing the right drums in your process—creates a safer workplace, reduces liability, and supports long-term sustainability across your entire waste management program.

Safe Storage And Transport Of Chemical And Waste Drums

Proper Storage Practices

Chemical drum storage areas should be designed to prevent contamination, fire hazards, or accidental release. Facilities must follow both OSHA and EPA guidelines for proper containment and spacing, as well as any state-level regulations that govern hazardous material management. The design of a storage area should also account for drainage control, ventilation, and emergency access to ensure quick response in case of leaks or spills.

Key Storage Recommendations

-

Segregate waste by hazard class: Keep acids away from bases, flammables away from oxidizers, and incompatible materials in separate containment areas to prevent reactions.

-

Use secondary containment: Spill pallets, berms, or containment trays should be installed to capture potential leaks before they reach soil or drainage systems.

-

Label all drums clearly: Include the words “Hazardous Waste,” accumulation start dates, hazard symbols, and generator information to comply with EPA and DOT labeling requirements.

-

Control environmental conditions: Maintain consistent indoor temperatures, reduce humidity, and avoid exposure to direct sunlight or freezing conditions that can compromise container integrity.

-

Inspect regularly: Check for signs of corrosion, leaks, bulging, or label deterioration weekly. Record inspections to maintain documentation for audits and compliance reviews.

Drums should always be stored upright, fully closed, and secured to prevent tipping or rolling. Facilities with limited space should implement racking systems or palletized setups that allow for safe stacking without damaging drum surfaces or seals. Aisles must remain clear and wide enough for forklifts or spill response equipment to move freely, ensuring quick and safe access in case of an emergency.

Proper ventilation is another critical factor—especially when storing volatile chemicals. Ventilation systems should prevent vapor accumulation that could lead to fire hazards or employee exposure. When feasible, storage areas should also include flame arrestors, grounding systems, and spill containment alarms to enhance overall safety.

Transporting Hazardous Waste Drums

Transportation adds another layer of responsibility. Spills or leaks in transit can cause environmental damage, trigger costly cleanup efforts, and lead to serious regulatory penalties. Each shipment must comply with U.S. Department of Transportation (DOT) regulations and, if applicable, international standards such as the International Maritime Dangerous Goods (IMDG) Code.

To ensure safe shipping:

-

Only use UN rated hazmat drums or DOT approved hazmat containers designed for the specific material type and hazard class.

-

Inspect drums before loading to confirm that there are no visible cracks, dents, or residue buildup that could weaken the structure.

-

Load drums upright, using pallets or racks to prevent contact damage. Secure them tightly with straps or containment systems to stop shifting during transport.

-

Ensure vehicle floors are clean, level, and equipped with non-slip surfaces.

-

Maintain complete shipping manifests, safety data sheets, and emergency contact information with every load.

Drivers and transport personnel should be trained in hazardous material handling procedures, including how to recognize leaks, secure cargo, and respond to emergencies. Regular vehicle inspections and proper route planning also reduce the likelihood of accidents or regulatory issues.

Facilities that follow these best practices significantly reduce their risk of incidents while ensuring full compliance with federal, state, and international transportation laws.

EPA Rules for Empty Drums

Even empty containers that once held hazardous materials must be handled carefully. According to EPA standards, a drum is considered “empty” only if all contents have been removed by normal means (such as pouring, pumping, or aspirating) and no more than one inch or 3% of residue remains inside. These guidelines fall under 40 CFR §261.7, which helps ensure that leftover residues don’t cause contamination or chemical reactions when drums are stored or reused.

Empty drums should be stored separately from full containers, clearly labeled as “Empty – Previously Contained Hazardous Waste,” and kept in areas with proper containment. They should be cleaned, recycled, or reconditioned through approved facilities. Improper disposal of contaminated containers can result in significant environmental violations and fines.

Facilities that use Gorilla Drum collapsible hazmat storage drums benefit from easier handling and more efficient space use. Once emptied, these drums can be collapsed and stacked flat, reducing warehouse clutter and simplifying recycling or reuse processes.

Spill Prevention and Response

Every storage or transport system must include a spill response plan. Even with careful planning, accidents can happen, so having proper procedures in place is essential. Spill kits, absorbent pads, neutralizers, and PPE should be accessible in every storage and loading area. Employees should receive ongoing training on spill containment, cleanup, and reporting procedures.

Facilities should also conduct spill response drills regularly to ensure that staff can act quickly during an actual event. Prompt response minimizes cleanup costs and environmental impact while ensuring compliance with EPA and OSHA requirements.

Gorilla Drum containers feature reinforced closures, leak-resistant seams, and double-sealed lids—designed to provide maximum protection during both storage and transport. Their collapsible construction and rugged materials further minimize leak risks, making them ideal for long-term containment of chemical and hazardous waste.

By implementing these best practices for safe storage and transport, organizations can ensure that hazardous materials remain secure throughout their lifecycle. With proper training, certified equipment, and reliable containers like those from Gorilla Drum, facilities can meet compliance standards, protect the environment, and maintain operational efficiency.

55 Gallon Drum Options For Hazardous Material Disposal

Traditional 55 Gallon Drums

A 55 gallon hazardous waste drum is typically made from either carbon steel, high-density polyethylene (HDPE), or a composite of both.

-

Steel drums provide durability and are ideal for flammable liquids or high-density materials.

-

Plastic drums resist corrosion and are suited for acids, alkalis, and water-based waste.

-

Composite drums combine materials to enhance strength and chemical resistance.

These traditional designs are still widely used, but they come with limitations—mainly weight, space inefficiency, and single-use waste.

Limitations of Conventional Drums

While effective for containment, rigid drums occupy the same amount of space whether full or empty. This leads to high storage and freight costs, especially for companies managing large waste volumes. They also require more handling equipment and often must be reconditioned or replaced after limited use.

The Rise of Collapsible Hazmat Drums

Collapsible hazmat drums address these inefficiencies with innovative, space-saving designs. Made from reinforced polypropylene, these lightweight containers fold flat when not in use, saving up to 80% of storage space.

Their high strength-to-weight ratio makes them just as reliable as steel or plastic drums, but far easier to handle. Each drum is tested and certified as a UN rated hazmat drum and DOT approved hazmat container, ensuring compliance with domestic and international regulations.

Advantages of Collapsible Drums

-

Space Efficiency: Collapsible designs minimize warehouse footprint.

-

Lightweight Construction: Easier to move and transport, reducing strain on workers.

-

Durability: Resistant to punctures, corrosion, and extreme temperatures.

-

Sustainability: Reusable and recyclable materials lower environmental impact.

-

Cost Savings: Reduced storage, transport, and replacement costs.

Collapsible hazmat storage drums are ideal for companies seeking a balance of safety, efficiency, and sustainability in their waste management systems.

Handling Hazardous Liquids and Solids

A high-quality hazmat barrel must handle liquids, solids, and semi-solids safely. Gorilla Drum’s collapsible designs feature reinforced seams, durable zippers, and structured frames that maintain shape during filling and transport.

They are designed to store:

-

Flammable and combustible liquids.

-

Corrosive or toxic chemicals.

-

Contaminated solids, sludges, or absorbent waste.

Each drum undergoes drop and stacking tests to confirm it can safely hold up under transport and storage stresses.

Comparison: Traditional vs. Collapsible

| Feature | Traditional 55 Gallon Drum | Collapsible Hazmat Drum |

|---|---|---|

| Material | Steel or Plastic | Reinforced Polypropylene |

| Storage Efficiency | Fixed volume | Collapsible, saves up to 80% space |

| Handling Weight | Heavy | Lightweight |

| Compliance | UN/DOT certified | UN/DOT certified |

| Reusability | Limited | Highly Reusable |

| Environmental Impact | Higher | Reduced through recyclability |

This comparison illustrates why collapsible hazmat barrels have become the preferred option for many modern industries.

Industry Applications

Collapsible drums are versatile and can be found in sectors such as:

-

Chemical manufacturing and blending.

-

Environmental remediation and cleanup.

-

Waste management and recycling operations.

-

Oil, fuel, and lubricant storage.

-

Pharmaceutical and laboratory facilities.

Their adaptability makes them suitable for nearly every waste management application.

Integrating Compliance, Safety, and Sustainability

Modern businesses must balance safety and efficiency with environmental stewardship. Using reusable, collapsible hazmat storage drums reduces overall waste generation and carbon emissions while maintaining full compliance.

How Gorilla Drum Supports Compliance

Gorilla Drum designs every container to meet or exceed international safety and performance standards. Each drum undergoes testing for structural integrity, leak resistance, and chemical compatibility.

By investing in Gorilla Drum products, facilities can confidently manage hazardous waste while reducing long-term costs and environmental impact.

Sustainability and Cost Efficiency

Unlike single-use steel or plastic barrels, collapsible drums can be reused many times, significantly lowering disposal costs. They also allow companies to store and ship more units per truckload, reducing overall transportation expenses and emissions.

Sustainability initiatives are increasingly shaping procurement decisions across industries. Gorilla Drum provides an environmentally responsible solution that doesn’t compromise performance or safety.

Combining All Three: A Complete Approach to Waste Management

Choosing the right hazmat drums requires a holistic view of the entire waste management process—selection, storage, transport, and disposal.

-

Understanding UN and DOT ratings ensures regulatory compliance and safety certification.

-

Implementing best practices for chemical storage and transport minimizes risk and prevents environmental damage.

-

Selecting advanced 55 gallon drum options, like collapsible containers, improves efficiency and sustainability.

By integrating all three elements, facilities create a safer, cleaner, and more cost-effective waste management system.

Gorilla Drum: The New Standard in Hazardous Waste Containment

Gorilla Drum leads the industry in innovative containment design. Each drum combines strength, compliance, and sustainability to meet the demands of modern hazardous material management.

Key features include:

-

Collapsible frame for efficient storage and transport.

-

Durable polypropylene construction for chemical resistance.

-

Reinforced closures and leak-resistant zippers.

-

Compliance with UN and DOT standards.

-

Compatibility with liquids, solids, and sludges.

Facilities using Gorilla Drum benefit from reduced storage costs, improved worker safety, and measurable sustainability gains. These drums represent the future of chemical drum storage—safer, stronger, and smarter.

Final Thoughts

Choosing the right hazmat drums for waste storage requires understanding regulations, container performance, and operational needs. Whether you’re handling small batches of laboratory chemicals or large industrial waste streams, selecting certified, sustainable containers ensures safety, compliance, and long-term efficiency.

From UN and DOT compliance to collapsible drum innovation, Gorilla Drum provides comprehensive solutions that redefine what hazardous waste containment can be.

For more information on compliant and sustainable hazmat storage drums, call +1 800-758-8079.